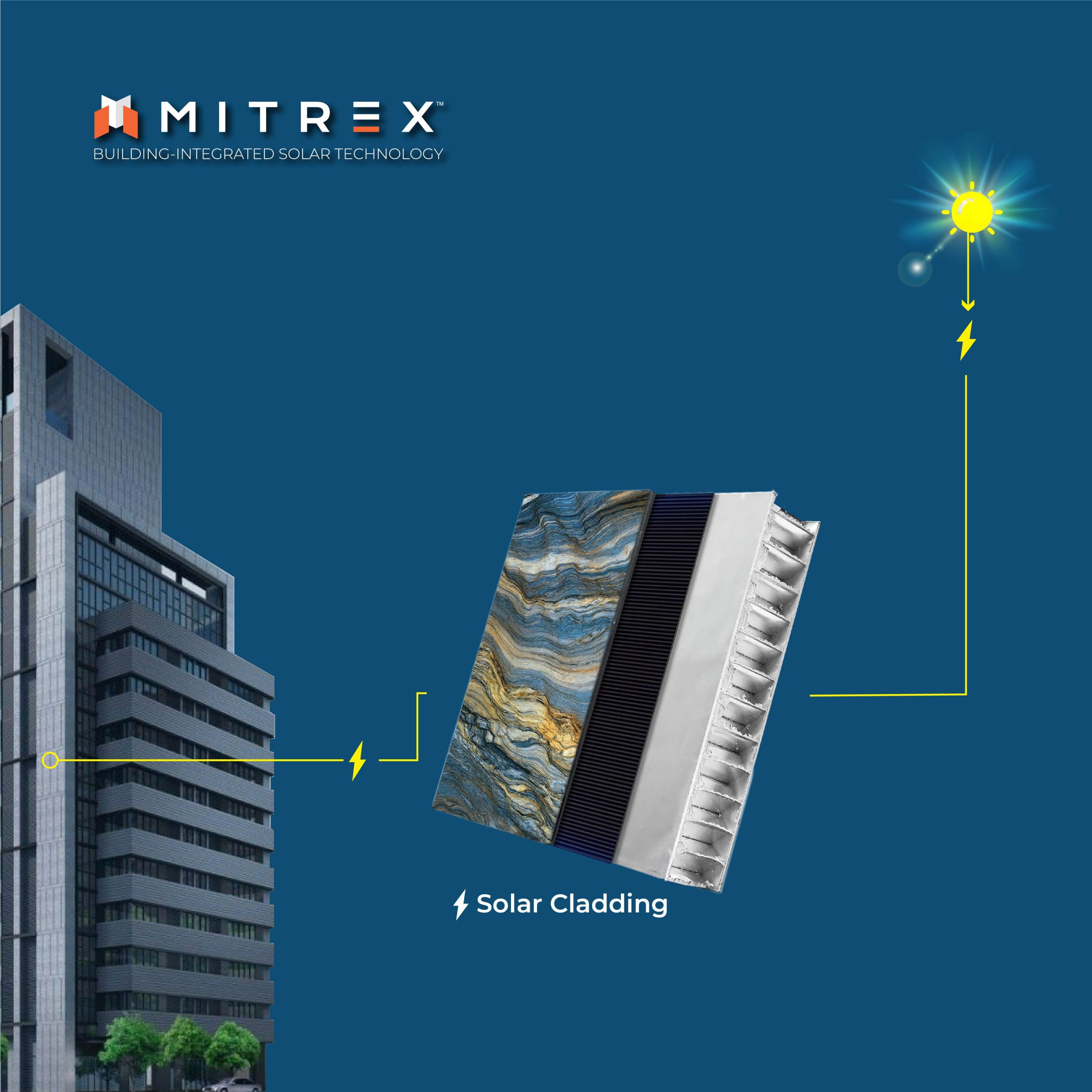

Mitrex is a Canadian manufacturing leader in solar technology. Offering solar cladding, windows, roofs, and panels, Mitrex is committed to providing an effective eco-friendly energy system that does not compromise aesthetics. Their innovative building-integrated photovoltaic (BIPV) was designed to offer solar energy in a wider range of colours, textures and shapes.

After discovering the potential energy that was going to waste, CEO Danial Hadizadeh travelled and researched extensively to find how solar technology was being cultivated around the world. Mitrex is confident that they are providing Canadian architects and developers with the best design choices for their vision. OnSide Media had the opportunity to speak with Danial to learn more about the origin of Mitrex, the journey to where it is today, and the logistics of their innovative BIPV.

How did Mitrex begin as an engineering company? What made you decide to pursue aesthetically pleasing solar panels when choosing to improve the environment?

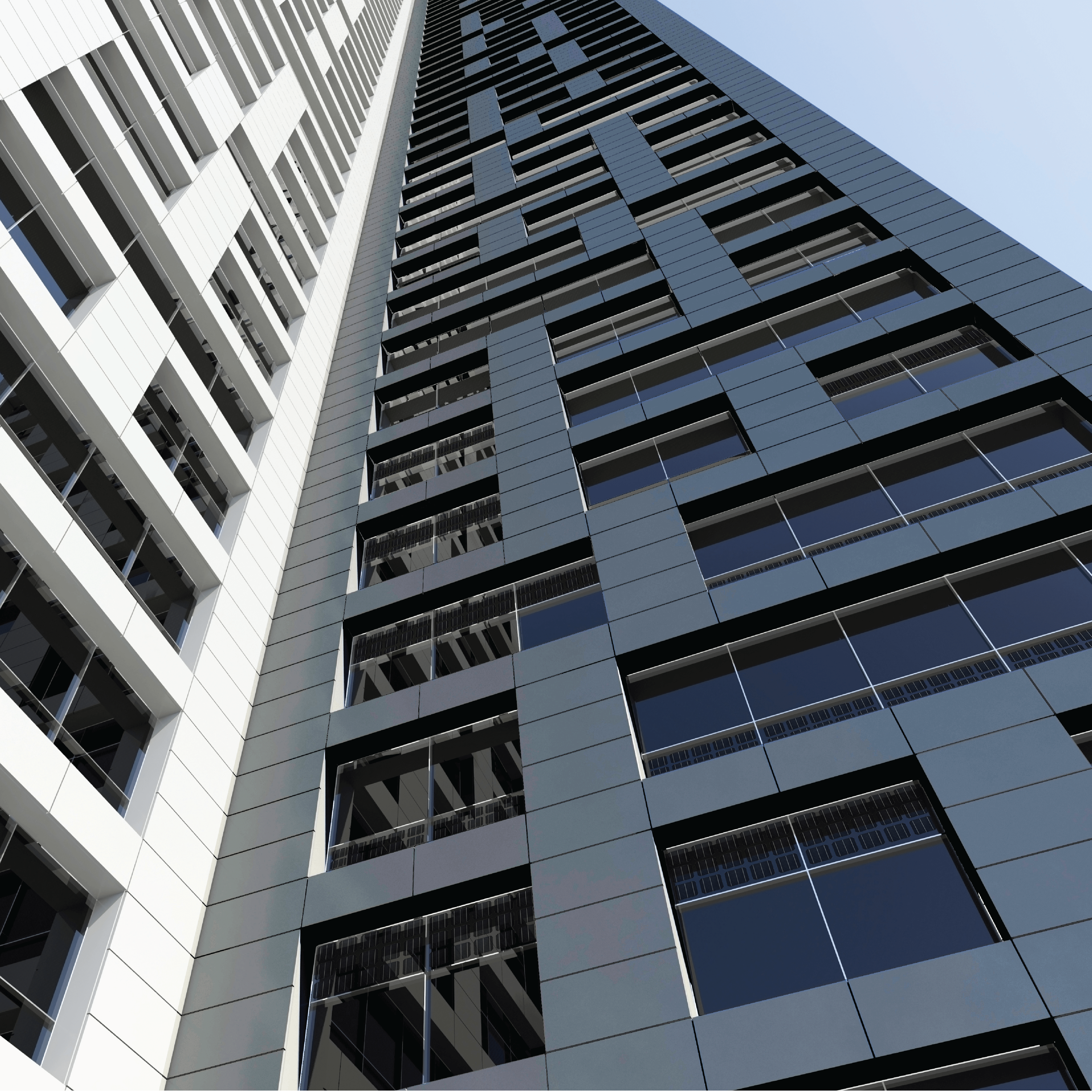

Danial Hadizadeh: I can tell you the exact moment. I was standing in front of a high-rise building that we were supplying material to. It was summer, and I was leaning against the wall. I could feel the heat and how warm the building was. I actually measured the temperature of the building. It was 65 degrees in the building, and the temperature was 29. So the building was much warmer because of the direct sunlight. I began to think of the energy that was going to waste.

Why are we just warming the planet and putting these panels on the wall? While we can capture this energy, convert it into electricity, and use it? The journey started from there. I was hiring people, researching, reading books, bringing onboard investors, putting up my own investment. That was the moment I thought solar could be an option. I was taking into consideration who had done it before and what the costs were.

How do you decide which companies to work with? Do clients seek your services? Or do you pitch your services to companies?

DH: We have to introduce ourselves to architects and engineers so that they know we exist. If they do not know we are here, they wouldn’t know that this is an option. Once they know, they are excited and want us to be apart of their standard process. So yes, we do introduce ourselves to developers, but we also get a lot of requests globally.

From Singapore to Austrailia, Dubai, many different countries. We are doing our best to help as many clients as we can. Our goal in Mitrex is not to sell materials or to just make money, but it is to make a difference first. Then, we are sure the money will follow after.

What is the testing process like for your engineers? How long does it take to find an eco-friendly solution that works?

DH: We started Mitrex basically as a prototype and testing only. We set up our internal lab, bought testing equipment, and hired professionals to test. The initial part was about three years to get to a working prototype. From there, we started the manufacturing part, which we did the testing with third-party companies. That brought us to 2019 when we started the plant and production line, and that was the beginning of the production line for Mitrex.

How long did it take your team to develop the revolutionary building-integrated photovoltaic (BIPV)?

DH: The concept behind the building-integrated photovoltaic is not new. Other people have also thought of it, but there were obstacles. I went everywhere from Europe to Asia to the Middle East, to see what companies were involved and who is doing this the best. Is anyone close? No one wants to reinvent something. If it already exists, lets just bring it to North America and introduce it.

I noticed the limitation and potential at the same time. The BIPV was limited in shapes, sizes, textures, and colours. It was also very expensive. From an architect’s perspective, it is inconvenient to work with only two or three colours and two sizes. You would have to change it and redo the whole thing. Those are the triangles of Mitrex. We should be able to produce in a high volume to lower the cost. We should also have all different sizes, colours, and textures. Those were the questions we had to answer and the criteria we had to meet.

Which of your products was the most challenging to cultivate? Which was the easiest?

DH: The first model, which was the cladding, took the longest. It was not necessarily the hardest, but it was the first one that we attempted. We were learning, and we were improving ourselves. We develop the newer products quicker now, but we are constantly raising the bar and are looking at products that are a lot more complex.

As far as solar panels and BIPV goes, we have mastered it. Now we know what direction to go. One direction is to improve our existing products, and the other is looking into new product. Ideally, you want to have a building with the solar growing on top of it.

For more information kindly visit:

Website: https://www.mitrex.com/